Milwaukee Blog

The industrial process of cheesemaking

The industrial production to make cheese starts with the main ingredient, raw milk. Most of the cheeses are made from cow milk but there a cheeses that are made from goat or sheep milk.

The first stage is called Pasteurizing. In this stage the raw milk should be pasteurized (heat-treated) in order to kill any unwanted bacteria. Then the milk is transfered into big vats for the next step.

The second step is a process where the milk is separated into solid curds and liquid whey. During this step the monitoring of the pH level is critical. Separating the milk happens by adding starter (bacterial) cultures and rennet to the pasteurized milk. The bacterial cultures are starting to consume the lactose which is the only primary sugar in the milk and create lactic acid during the fermentation.

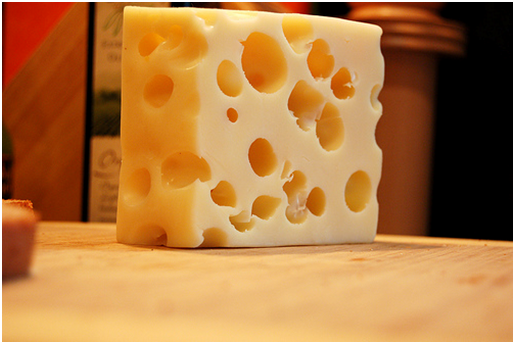

The Propionibacterium freudenreichii bacterium produce carbon dioxide while aging giving the Swiss cheese its holes. The lactid acid is causing the pH of the milk to drop while developing the flavor of the cheese. Depending on the cheese type, at a specific pH level the rennet is added which sets the cheese into a firmer, stronger substance. While dilluting the rennet enzymes it is also critical to measure the pH of the water which is used for the dilluting since water which have a pH levels of 7 or higher can neutralize rennet.

Once the curd reaches a pH level of 6.4 and a firm rubbery substance the curd is then cut into small pieces, stirred and cooked. Then the remaining liquid whey is drained from the vat.

After the liquid whey is trained the curd forms a thick mass. These mats are cut into pieces and piled on each other while they are flipped periodically (10-15 minutes).This step helps to remove more whey and allows the fermentation to continue and form a dense texture which is cut again into smaller pieces for the salting where the curd pieces are mixed with dry salt. After the salting the curd pieces are placed in molds and pressed into blocks to form the cheese.

Afterward the cheese blocks are stored in coolers from a few months to even several years depending on the cheese type until it is packaged and sold in supermarkets.